Achieving Operational Excellence: Framework, Examples, Tools & Hiring |

您所在的位置:网站首页 › michael page hiring nam continuous improvement › Achieving Operational Excellence: Framework, Examples, Tools & Hiring |

Achieving Operational Excellence: Framework, Examples, Tools & Hiring

How to Achieve Operational Excellence: Framework, Examples, Tools & Hiring

Featured Bonus Content: Download the FREE Operational Excellence Implementation Plan Workbook! Click Here To Download It. This guide will show you everything you need to know about operational excellence. First, we’ll help you understand what operational excellence really is. Then we’ll show you examples of how other companies have achieved it, and how you can implement and achieve it for yourself. We’ll even guide you through the process of hiring someone who can manage operational excellence in your organization. Sound good? Let’s dive right in. Table of Contents Chapter 1: What is Operational Excellence? Chapter 2: Examples of Operational Excellence Chapter 3: How to Achieve Operational Excellence Chapter 4: Overcoming Operational Excellence Challenges Chapter 5: Hiring an Operations Excellence Manager Chapter 6: Recommended Reads for Operational Excellence Chapter 7: Frequently Asked Questions about Operational Excellence What is Operational Excellence? Definition of Operational Excellence

Definition of Operational Excellence

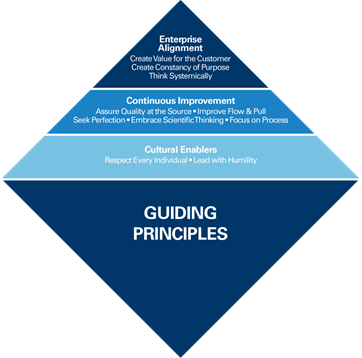

The founder of The Institute for Operational Excellence, Kevin J. Dugan, defines operational excellence as a point where every employee can see the flow of value to the customer and fix it when the flow is interrupted or breaks down. In an operationally excellent organization, everyone knows their respective contribution to the flow of value to the customer. They can identify when this flow is normal or abnormal, and know how to restore any abnormality without the assistance of management. Because every employee is proactively responsible for their tasks, leaders of operationally excellent companies can shift their focus from managing day-to-day activities and focus on continuous innovation and other activities to increase recurring revenue. History of Operational ExcellenceWhile many consider the Japanese engineer Dr. Shigeo Shingo (1909–1990) to be the father of operational excellence, we believe that the innovative leadership and management techniques developed by engineers and scientists since as far back as the 18th century have influenced what we know as operational excellence today. In the 18th century, Adam Smith introduced ideas around the division of labor. Frederick Winslow Taylor, a leading proponent of scientific management in the 19th century, sought to engineer workflows for improved efficiency. In 1913, Henry Ford, founder of the Ford Motor Co., played a leading role in developing the assembly line. Taiichi Ohno worked with Shigeo Shingo in 1950 to help Toyota develop a system that could manufacture an automobile with fewer resources (i.e., machines, people, space, time, etc.). This was the birth of the Toyota Production System that later became lean manufacturing or “lean.”In the 1970s, Dr. Joseph M. Juran developed the Juran Trilogy (quality planning, quality control, and quality improvement) and established the Juran Institute.In 1986, Bill Smith, a senior engineer and scientist at Motorola, formulated the Six Sigma methodology. His research was based on the previous work of Dr. Joseph M. Juran, W. Edwards Deming, and others.The 2000s saw the combination of Lean and Six Sigma, plus other continuous improvement methods. Operational Excellence vs. Continuous ImprovementOperational excellence and continuous improvement do not mean the same thing. They’re also not two completely different methods. Successful companies need a bit of both methods to work. Continuous improvement involves making each existing process perfect by consistently adjusting them to reduce waste, improve quality, and maximize human potential. It is a never-ending journey that ensures every process is always performing at its height of efficiency. Continuous improvement guarantees more efficient processes, but if leaders are always concerned with fixing and improving the same processes, they will not have time to innovate and focus on other revenue-growing activities. There is no guarantee that the changes made will lead to growth or save the company if customers no longer want their product. This is where operational excellence comes in. To achieve business growth and continue to innovate while continuously improving, an organization must reach a state of operational excellence. At operational excellence, everyone in an organization knows their contribution to normal flow, can identify abnormal flow, and implement the standard methodology for correcting processes when they go wrong without management intervention. Operational excellence removes the need for management involvement in day-to-day activities, and permits leaders and managers to spend their time innovating and working on activities that generate top-line growth. Operational Excellence and the Flow of Value Seeing the Flow of ValueOperationally excellent organizations set up visual systems to depict the flow of value from the beginning of production until it reaches the customers. These visual systems communicate the time required to perform each process so that every employee can see exactly where they are in the value stream, and how the flow works. Operationally excellent visual systems are so simple that a visitor can look at them and tell if they are on track without asking any questions, requesting any reports, or looking at any computer printouts. Fixing the Flow of ValueNo matter how excellent operations are, there is always a possibility for disruption. With OpEx, what matters is not whether or not the flow of value breaks down, but how employees fix this flow when it does. So, what do employees do when an operationally excellent flow of value breaks down? Instead of calling the supervisor, they ask, “What’s the standard procedure for fixing this?” Standard work is the fuel that drives operational excellence. It is the standard procedure performed by every employee when an abnormality occurs in their section of flow. Thanks to standard work, decision-making is kept to a minimum, and employees can repeat the same process every time the flow of value is disrupted. What Are the Principles of Operational Excellence?The guiding principles of operational excellence, also known as the Shingo Guiding Principles, are the basis of building a sustainable culture of operational excellence in any organization. Shingo’s ten principles serve as a foundation for anyone hoping to compete and attain market leadership through operational excellence. Each principle is grouped into either of these three categories: Cultural enablersContinuous improvementEnterprise alignment Source Source

Every year, the Shingo Institute at the Jon M. Huntsman School of Business, Utah State University, offers an award for operational excellence to outstanding organizations. This award is based on company culture, company results, and how well every employee demonstrates Shingo’s ten guiding principles of operational excellence. These are the ten core principles of operational excellence: Respect every individualWhen employees feel respected, they give their hands, minds, and hearts to their work. The culture of respect in any organization reflects in how everyone is treated, even customers and suppliers. From the executive level down to the employees, everyone should understand the importance of respect, and commit to treating everyone like a fellow human being with worth and potential. 2. Lead with humility Leaders who acknowledge when they are wrong and abandon bias and prejudice to pursue a better way of doing things will see their team members start to develop this same attribute. If every leader is willing to seek input and listen to constructive criticism, team members will feel respected and freely give their creative abilities. 3. Seek perfection Although perfection may never be achieved, actively striving for it in every process will create a mindset and culture of continuous improvement. Every employee should have the “it can always be better” mindset. 4. Embrace scientific thinking Without repeated cycles of experimentation, continuous learning, and failure, innovation and improvement will never happen. Develop a culture of exploring new ideas and consistently refining your team’s understanding of reality. 5. Focus on process The American statistician Dr. W. Edwards Deming postulated that 85% of quality problems are in the processes and not people. And before he died, he admitted he was wrong and said it was 96%. All outcomes are the consequence of a process. To improve quality, you need to change how the work gets done. When something goes wrong, don’t be quick to blame the people in charge—check the process. 6. Assure quality at the source When an error is detected, it should be corrected at the source. Perfect quality will only be achieved when every element of the process is made right at its source. 7. Improve flow and pull Maximize value for customers by supplying it in response to demand in an uninterrupted flow. While trying not to interrupt flow, you mustn’t oversupply to avoid waste. 8. Think systemically Think systemically when you’re trying to optimize the whole operation. You must first understand the interconnectedness of every person and process to make better decisions and improvements. 9. Create constancy of purpose Every employee should have an unwavering awareness and understanding of why the organization exists, where it is going, and how it will get there. This way, they can take risks with more confidence, and innovate and align all their actions to pursue one purpose. 10. Create value for the customer To the customer, value is getting what they want, when they want it. If you fail to deliver this effectively, your organization will have a short lifespan. Why is Operational Excellence Important?Operational excellence allows management to plan, innovate, and focus on business growth instead of spending time putting out business fires. 4 Core Benefits of Operational Excellence Improved teamwork and innovative problem-solvingTeam members feel more responsible for their part of the process and are more likely to develop new ways to solve problems and improve processes. 2. Problems are detected earlier. Because visual systems are used to depict flow of value from the beginning of production until value reaches the customers, every employee can see exactly where they are in the value stream. If anything is out of place or late, they’re able to correct the problem at its source and restore the flow to its original state. 3. Operations are lean, predictable, and scalable. Operational excellence demands that processes are efficiently carried out and are as consistent as possible. This predictability allows for better planning and expansion. 4. Customers are kept happy. When processes are operationally excellent, you will meet the demands of customers when they want it without creating any waste. Management will also have time to carry out market research to find more ways to create value for the customers, whether by improving an existing product or creating a new one. What Industries Can Benefit from Operational Excellence?Over the years, various industries have utilized operational excellence either directly or indirectly to build lean, predictable, and scalable processes that allow them to stay relevant and ahead of the competition. Companies like Toyota, Motorola, Amazon, Apple, Disney, Tesla, Fastcap, and GE have been praised for the different ways they have utilized operational excellence to stay ahead of the competition. OpEx concepts like continuous innovation, flawless service, providing a fun working environment for employees, and creating a culture where everyone is constantly aware of the company’s purpose can be used by any industry to attain market leadership. Examples of Operational Excellence Examples of operational excellence in manufacturing: Toyota and Jabil

Examples of operational excellence in manufacturing: Toyota and Jabil

Many manufacturing companies use operational excellence to reduce the amount of waste produced and make process flow more constant and predictable. ToyotaIn 1950, Toyota Motor Company was struggling to avoid bankruptcy after the Second World War. They were producing only 2,685 cars per year while their major competitor, Ford Motor Company, produced 7,000 cars per day. They turned to engineers Shigeo Shingo and Taiichi Ohno, who created a lean manufacturing system to manufacture more cars with fewer machines, people, space, time, and energy. Since then, Toyota has become one of the largest, most profitable automobile manufacturing companies. JabilFounded in Michigan in 1966, Jabil is the world’s third-largest electronic manufacturing services provider with a fiscal 2016 revenue of $18.4 billion and 180,000 dedicated employees. In this case study by BTOES insights, Jeff Porada, global director of Lean Six Sigma at Jabil, explains how by engaging leadership with operational excellence through strategic alignment and visual management, they have survived over 50 years of business—profitably and with a vision for another 50 years. Porada explains that the way to survive and remain relevant in a competitive industry is by driving a system of continuous transformation. He also stated that principles and not tools lead high-performance organizations. Instead, tools are used to help strengthen and encourage adaptability and resilience. Example of operational excellence in information technology: WiproOperationally excellent IT companies focus on continuously improving processes and culture. Wipro delivers IT services, business and technology consulting, IT outsourcing, and system integration services and solutions globally. In May 2007, Wipro was contracted by Order Entry to help solve their inability to fulfill orders on time. This problem was causing customers to lose trust in Open Entry and impacted the flow of revenue. Wipro improved the operational excellence of Order Entry’s order management system by: Improving customer experience—they provided a more flexible and predictable service and lead times. Fulfilling orders at a predictable cost base.This project won Wipro the Business Transformation & Operational Excellence Award for Best Project in Customer Experience. Example of operational excellence in healthcare: SickKidsOperational excellence in healthcare is focused on empowering staff to deliver safe and reliable care, improving processes to use resources more efficiently, eliminating mistakes and unnecessary procedures, and improving health outcomes. SickKids in Toronto is one of the world’s leading children’s hospitals. They began their operational excellence journey in 2012 with a successful multi-year continuous improvement program. To achieve operational excellence, SickKids had a dedicated team of five full-time staff, mainly with industrial engineering backgrounds, whose job was to empower staff to: Identify improvement opportunitiesDesign efficient processesImplement viable solutionsThis team offered training in Daily Continuous Improvement Programme and process improvement at the yellow and green belt level. “Organizations can only achieve true excellence when their employees are legitimately empowered. Implementing a lean management system is one powerful way to maximize the engagement of employees in organizational success.” —Jeff Mainland, executive VP, SickKids Example of operational excellence in real estate: MonteVista HomesBecause of how technical construction work can be, operational excellence in real estate is usually focused on documenting and streamlining processes to ensure a high level of efficiency. MonteVista Homes builds quality, energy-efficient new homes in Oregon. Before operational excellence, they suffered major setbacks caused by ineffective business process documentation. In an interview with SweetProcess, Luke Pickerill, president of MonteVista homes, said: “We employ about 75 to 100 individual trade partners to get these homes built. Each trade partner may have anywhere between one to 40 employees. The most challenging part is the operational organizational side of it. As one trade gets ahead of schedule or is late, that can affect all other buildings simultaneously.” Since deciding to try a more operationally excellent model using SweetProcess, MonteVista Homes has overcome its challenges with inconsistent processes. They’re now able to document processes in a secure and easily accessible way and onboard new employees and contractors in only a few hours. Plus, management can finally focus their attention on finding new ways to satisfy the customer and grow revenue. Example of operational excellence in marketing Mudd AdvertisingMudd Advertising is a top advertising agency in the United States, specializing in the automotive industry. For over 30 years, Mudd has worked directly with dealers across the U.S., servicing no fewer than 3,000 accounts annually. In this interview, Dave Meindl, senior advisor of digital technology and performance at Mudd, told us that his greatest challenge was that Mudd seemed to have no existing system in place. Processes were disorganized and undocumented. He said: “They had no system for keeping track of how things were done. I’m assuming it just sort of happened by word of mouth or something. As soon as I got there and saw that there was no way to keep track of these processes, I immediately said we needed to solve this problem; otherwise, there’s going to be complete chaos.” After working with SweetProcess to create more excellent operations, Meindl was able to: Instill efficiency via proper documentation. Processes became more efficient, and employees now make fewer mistakes. Save costs by preventing avoidable expenditure. Mudd achieved this by leaning up their processes and taking out every unnecessary step in the flow of value to the customer. Ensure high-quality performance with a reference document. Employees now have a reference document that they can turn to for every process. If the process flow is disrupted or becomes abnormal, they can reference these documents and fix flow without any assistance from management. Fast-track employee onboarding and training. For Mudd Advertising, this is one of the highlights of using SweetProcess. New employees can simply follow the documented steps and execute their tasks successfully without any help or training.You can learn more about SweetProcess or claim your 14-day free trial without any initial commitment—not even a credit card. How to Achieve Operational Excellence

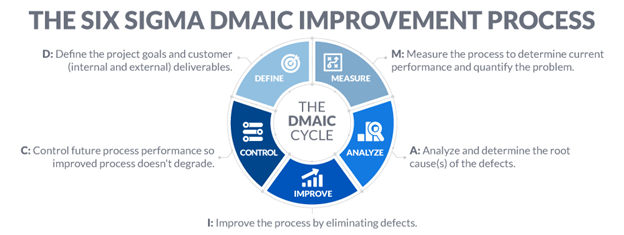

This chapter will discuss the steps involved in implementing a successful operational excellence strategy in your organization. The 5 Keys to Achieving Operational ExcellenceTo successfully implement an operational excellence strategy in your organization, there are five things we suggest you put in place before anything else. 1. An honest assessment of where you are You need to first know where you are before deciding where you want to go and how you’ll get there. Megan Burns, regional managing director at InSource Solutions, suggests that the best way to do this is by assessing your organization’s maturity level in four key areas: Engagement of your peopleProcess capabilityLevel of technologyHow disciplined you are at the execution2. Clear vision, goals, and objectives When implementing company-wide change, it helps to start with a clear vision. This vision can be product-focused, growth-focused, market share-focused, etc. It must be consistently communicated to every leader and employee so that team members can take risks, make decisions, and align their efforts toward achieving the same goals. 3. A supportive and engaged team It’s easier to get the time and resources required to implement a company-wide OpEx strategy when everyone is on board. From the executive level to the lowest level employees, everyone should be educated on the benefits of operational excellence for themselves and the entire organization. 4. Commit to continuous improvement Developing a culture of operational excellence will require a commitment from every team member to be consistently open to change. Employees should always be ready to give up their old way of doing things for better ones. 5. The right metrics Not being able to measure progress can be detrimental to your OpEx journey. It helps to have meaningful KPIs that align with your company’s vision, goals, and objectives. With this in place, employees can track results and stay encouraged to keep improving, knowing that their efforts bring visible results for the company. How to Set Operational Excellence GoalsAchieving operational excellence is far from easy, and hitting your operational excellence goals will require a strong commitment from every leader and employee in your organization. To make it easier for everyone to come on board with your OpEx goals, it helps to align them as much as possible with your already existing business vision and strategy. To do this, we suggest that you answer these six questions before setting your operational excellence goals. What is your long-term vision for OpEx within your organization?Does this vision align with your organization’s business vision/strategy? If not, what changes can you make to fix this?What KPIs and metrics should be used to measure the impact of OpEx goals in your organization?What budget and resources do you have to implement an OpEx strategy?When will you deploy OpEx into your organization?What are the cultural changes that need to be made to sustain operational excellence in your organization?OpEx goals can be divided into three broad categories: 1. Financial goalsAs implied, financial goals are focused on money coming in and going out. Examples of financial goals: More sales.Reduced cost.Improved cash flow.A more efficient supply chain.Shorter payment cycles. 2. Operational goalsOperational goals are focused on improving productivity and the general quality of processes. Examples of operational goals: Fewer accidents and improved safety.Improved product or service quality.More consistent product/service quality; reduced defects and error rates.Higher output and improved employee productivity.Fewer regulatory or compliance issues.Reduced carbon footprint.Improved customer satisfaction. Greater customer retention. 3. Cultural goalsCultural goals are targeted at improving your employees’ capabilities and commitment to achieving operational excellence. Examples of cultural goals: Higher number of employees trained in structured problem-solving.Improved team member accountability. Increased employee involvement in continuous improvement activities.Improved employee career satisfaction.Greater employee engagement. What Are Operational Excellence KPIs and Metrics?Metrics and KPIs take goal setting a step further. While implementing your OpEx strategy, having the right metrics will help you track and evaluate your progress over time, make sense of data, and arrive at meaningful conclusions. Measuring your operational excellence metrics will save you time, effort, and resources spent on non-value-added work. You will be able to identify where your team is succeeding, where you need to increase your effort, and what parts of the process need to be adjusted, changed, or completely removed. Here are five examples of metrics and KPIs you can pay attention to on your OpEx journey: Customer satisfactionConsistently measuring customer satisfaction will help you identify process gaps and lapses within the organization. It will also help you prioritize the different functions that require attention and focus on solving the most urgent ones first. Examples of KPIs for measuring customer satisfaction: Voice of Customer (VOC).Customer satisfaction (CSAT).Net promoter score (NPS).Overall satisfaction metric. Complaint rate.Service-level agreements met ratio.Call pickup time.Time to resolve the issue. E-commerce abandon rate. Renewal and retention rates, etc. Culture and employee satisfactionHighly engaged teams show a 21% greater profitability. Measuring culture and employee satisfaction KPIs will help you improve performance faster by revealing the most important areas to your employees. Examples of KPIs for measuring culture and employee satisfaction: Employee satisfaction score. Number of trainings completed. Employee retention. Ratio of internal to external hires, etc. ProductivityProductivity is a versatile metric. You can select your KPIs based on the business goals you’re trying to achieve for the time period by deciding the numerator and denominator for the output per unit (productivity). If revenue exceeds sales and marketing expenses, you’re on the right track. Examples of KPIs for measuring productivity: Sales productivity across accounts.Return on investment (ROI).Ratio of revenue to employees.On-time delivery.Capacity utilization.Downtime. Overall equipment effectiveness. Operating rates.Output.Labor utilization. Operating margin, etc. Financial (cash flow and gross margin)Finance is arguably the best indicator of business health. Paying attention to it can help you pinpoint operational inefficiencies, reduce unpleasant surprises, and decide strategic initiatives for pricing, investments, and sales efforts. Examples of KPIs for measuring financial metrics: Gross margin—the higher the gross margin, the more excellent your processes are.Cash flow—DSO (days sales outstanding) and DPO (days payable outstanding).EBITDA (earnings before interest, taxes, depreciation, and amortization).Audit performance.Asset values and lifecycle cost projections.Compliance risk measure.Disaster recovery readiness metric. QualityThe quality of the product or service you offer is a great indicator of whether your processes are improving or not. Examples of KPIs for measuring quality: Error/defect rate. Order accuracy rate.Cost of poor quality.Volume of rejected products.Cost of rejected products. Number of change requests. Our Top 3 Operational Excellence MethodologiesThe three operational excellence methodologies discussed in this section are Lean manufacturing, Kaizen, and Six Sigma. Lean manufacturingLean manufacturing focuses on the systematic identification and elimination of waste in every process. Companies that implement the lean methodology center their attention on only the steps that add value in the process and try to eliminate as many steps that don’t. The goal is to reduce cost by producing more units with fewer materials. The key principles of lean manufacturing focus on improving the quality of products and services, eliminating anything that doesn’t add value, and reducing overall costs. The Lean manufacturing methodology identifies seven sources of waste: 1. Mistakes These are errors that need to be corrected or eliminated for the process to run smoothly. These errors often lead to defective products, which results in waste. 2. Overproduction Overproduction occurs when employees produce items before they are needed. 3. Over-processing This occurs when there are more steps involved in a process than needed. The time that could have been spent on more value-added work is wasted. 4. Transportation Transportation becomes wasteful when it involves unnecessary movement of materials or finished products. 5. Motion This source of waste is similar to transportation, except that it has more to do with the unnecessary movement of equipment or people. 6. Inventory This occurs when supply is not met by demand. Excess products may end up becoming waste. 7. Waiting Employees waiting unnecessarily long periods for feedback or instructions from management contribute to wasted time. Six SigmaSix Sigma is a systematic method of process improvement that focuses on improving quality and customer experience by reducing variation in production. Companies that implement the Six Sigma methodology do not produce at quality levels below 3.4 defects per million opportunities (DPMO). Six Sigma was developed in 1986 by Bill Smith, a senior engineer and scientist at Motorola, and is now popular among many Fortune 500 companies. Fifty percent of Fortune 500 companies today are said to have implemented Six Sigma to some degree. The Six Sigma methodology of reducing defects and variation is implemented using Deming’s DMAIC framework. DMAIC is an acronym for define, measure, analyze, improve, and control. Define: Define the problem.Measure: Quantify the problem by measuring the available data to discover what parts of the process need improvement. Analyze: Identify the cause of the problem and confirm with data. Improve: Solve the root cause and make changes in the process to eliminate the defects and wastes identified.Control: Control the improvements to keep the process on the new course. Kaizen methodThe word Kaizen is Japanese for “continuous improvement.” This methodology focuses on small, frequent, and consistent improvements to the existing work processes by every member of the organization, from the executive level to the lowest-level employee. It can improve quality, cost, delivery, management, safety, and just about any other aspect of the business. The Kaizen methodology teaches that small changes applied consistently will compound over time to produce big results. It also encourages innovation and teamwork by encouraging every employee to participate in the process of continuous improvement. Unlike some other operational excellence methodologies, the Kaizen methodology focuses more on improving culture than using or introducing tools. It can also be implemented alongside other methodologies like Six Sigma and 5S. Operational Excellence FrameworksOperational excellence frameworks are designed to help you transform your organization, continuously improve, and guide you through your OpEx journey. The three OpEx frameworks discussed in this section will help you: Align everyone in your organization with your business goals. Pinpoint the underlying causes of recurring problems within your organization.Implement new goals and policies. DMAIC Framework Source Source

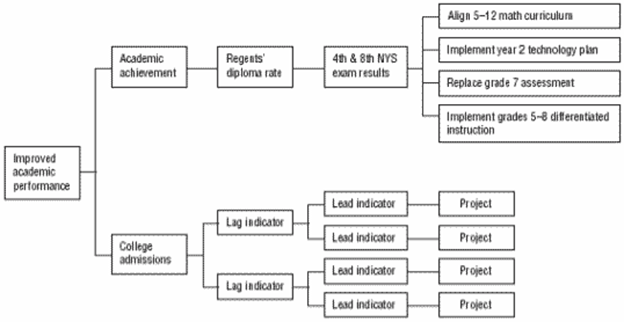

DMAIC is an acronym for define, measure, analyze, improve, and control. It is a data-driven OpEx framework of Six Sigma to identify the root cause of problems and develop ways to continuously improve existing processes. PHASE 1: Define: Define the problem.Examples of activities under Define: Developing a project charter: This is a document referred to during the project. It is adjusted as team members learn more as the project progresses. It documents: What the problem is. What’s the extent of the problem.What’s the business case. What are you going to gain out of this? (What’s your goal?) What’s in scope and what’s not in scope.Who’s on the team. What’s the timeline for improvement.Further steps may include: Getting customer data.Finding out the voice of the customer.Reviewing existing data.Drafting a high-level map of the process. Putting together your plan and assigning tasks. PHASE 2: Measure: Quantify the problem.This phase will help you separate what you think is happening from what’s actually happening. It takes out all human bias and allows only data to do the talking. Examples of activities under measure Evaluating existing measurement system. Observing the process. Gathering data. Making the process map a bit more in-depth. PHASE 3: Analyze: Identify the cause of the problem and confirm with data.Examples of activities under analyze Looking for patterns in the data. Use the analysis tool to get past the symptoms and get to the true root causes of the problem.Target the places where there’s a lot of waste—especially time.Examples of OpEx data analysis tools: Percentages or magnitude—pie charts/bar charts.Trends—line graphs. PHASE 4: Improve: Solve the root cause and make changes to the process to eliminate the defects and wastes identified in PHASE 1: Define.Examples of activities under improve: Using creativity exercises to identify the possible range of solutions.Picking the best solution. Reviewing best practices—see who else is addressing those problems and how they’re addressing them. Piloting that chosen solution. Putting together a plan for full-blown implementation. PHASE 5: Control the improvements to keep the process on the new course, maintain the gains, and pursue excellence. Root cause analysis frameworkThis framework is designed to help you identify the causes of recurring problems in your organization and develop a plan to solve them. Problems that aren’t resolved at their source will always resurface and may even become worse. In every process, the root cause is the core issue. It is the highest-level cause that triggers the cause-and-effect reaction that ultimately leads to the problem. Approaches to root cause analysis: Events and causal factor analysis This approach uses data gathered methodically to establish a timeline for the activities leading up to the accident or problem. It is mostly used for major, single-event problems like refinery explosions. Change analysis This approach focuses on analyzing the changes made in people, equipment, technology, etc., to determine what may have contributed to the problem. Barrier analysis This approach focuses on analyzing the controls that are already in place to detect a problem or prevent one from occurring. Management oversight and risk tree analysis This approach makes use of a tree diagram to figure out what occurred and understand why it happened. A tree diagram is a new management planning tool that depicts the hierarchy of tasks and subtasks needed to complete an objective. It starts with one item that branches into two or more, with each branch developing two or more branches of its own, and so on. Example of a tree diagram:  Source Source

Kepner-Tregoe problem-solving and decision-making This approach provides four distinct phases for resolving problems: Situation analysis.Problem analysis.Solution analysis.Potential problem analysis. 3. Hoshin Kanri frameworkThis framework is a strategic planning process designed to help you implement new goals and policies in your organization. The Hoshin Kanri framework will help you achieve two things: Align everyone within the organization with your vision and goals.Identify the root cause of problems and resolve them. Operational Excellence Implementation PlanA successful operational excellence implementation plan typically involves seven phases: PHASE 1: OrganizeTasks under organize include: Selecting your team members. Assigning roles. Defining your mission and vision. PHASE 2: Assess and documentTasks under assess and document include: Ranking processes by importance. Meeting with the frontline team to get input.Learning more about the processes that need improving.Collecting available data and documenting your current state. PHASE 3: Identifying improvementsTasks under identifying improvements include: Articulating process improvement initiatives. Outlining the cultural changes needed to support your implementation plan.Documenting project steps. Creating a timeline. PHASE 4: Goal SettingTasks under goal setting include: Defining your KPIs and ranking them by importance. Defining your goals and making them SMART (SMART is an acronym for specific, measurable, achievable, relevant, and time-bound). Assigning tracking and monitoring responsibilities. PHASE 5: ExecuteTasks under execute include: Communicating plans to leadership and management. Communicating plans to employees. Implementing culture-building exercises.Identifying needed resources. Implementing steps outlined in phase 3. PHASE 6: Evaluate ImpactTasks under evaluate impact include: Documenting improvements. Getting feedback from frontline staff about success and failure. Tracking performance against your set goals.Reporting progress to management. PHASE 7: ConsolidateTasks under consolidate include: Reviewing your operational excellence framework and making necessary changes.Creating a plan to continue improving processes.Defining steps to continually improve culture. Determining the next operational excellence initiative. Operational Excellence Best Practices Start by defining your goals

Start by defining your goals

What would you like to achieve with operational excellence? What process problems would you like to solve? Before anything else, you should first outline everything you want to achieve with operational excellence, from broad goals to specific KPIs. Choose a methodology that matches your strategyAfter defining your goals, choose a methodology that helps you achieve them as efficiently as possible. Get senior management on boardIt helps to get the support of senior management as early as possible to get the resources you need for your OpEx plan. Get employees on boardThe sooner you get employees on board, the better. Because your employees are the ones working on the processes, they’re the ones who experience the problems every day, and they’re also the ones who will implement your OpEx strategy. It helps to include them in the conversation as soon as possible to give you real-time insight into the problems they face, and share ideas on how they think it can be made better. Communicate consistentlyCommunication is the key to achieving operational excellence. Communication starts when you share your OpEx goals, objectives, and KPIs with the leaders and employees, and continues as you go on. Consistently providing feedback on the progress made will help everyone in your organization stay motivated and aware of their roles throughout the process. Give rewardsTo encourage employees to stay motivated, it helps to regularly recognize and reward staff who show exceptional support. Continue to improveOperational excellence isn’t something that you can achieve and decide to move on. For it to be sustained, it requires continuous improvement, communication, and workforce engagement. Operational Excellence Tool SweetProcessSweetProcess is a tool that helps you attain operational excellence by allowing you to document processes, procedures, and tasks in one place, so you can stay focused on growing your business. With SweetProcess, you can: Document procedures and repetitive tasks. Create, share, and ensure the correct adoption of your business’s policies.Craft, collaborate and refine processes so that your organization can continue to grow and improve. Manage tasks, track all the latest activity, or look back in the history of any task or procedure.Turn your existing procedures and policies into a knowledge base for your employees or clients. Overcoming Operational Excellence Challenges

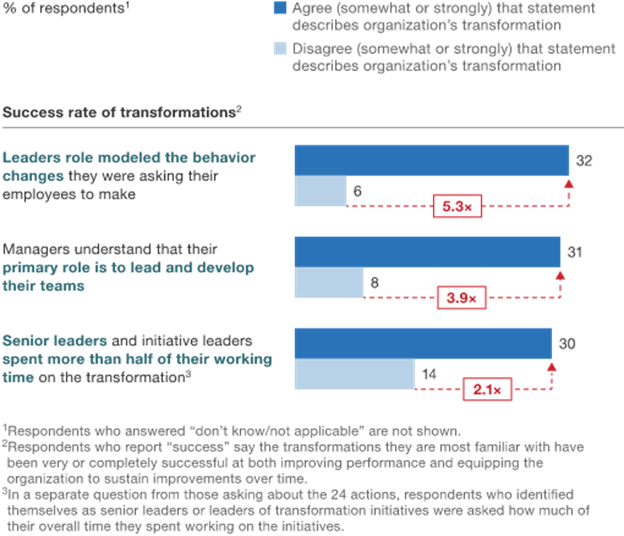

According to a global survey carried out in 2015 by McKinsey & Company, only 26% of company executives succeeded at effecting transformative changes like operational excellence in their organizations. In this chapter, we’ll address the five most common mistakes made by executives who failed at developing a culture of operational excellence in their organizations. We’ll also take a look at the four solutions suggested by McKinsey to help company execs implement transformative change more effectively. 5 Most Common Operational Excellence Challenges Ineffective cultural transformation effortsOperational excellence starts from company culture, and changing culture can be difficult. To successfully build a culture of innovation and continuous improvement in any organization, everybody from the executive level to the lowest-level employee must understand the vision and commit to doing their best to make it happen. Most organizations fail very early in their operational excellence journey because they don’t address the negative culture and values of the employees and replace them with new ones. Inability to sustain continuous improvement cultureContinuous improvement is about consistently finding more efficient ways to perform tasks. In their journey to operational excellence, most organizations jump right into finding ways to improve their processes. But after some time, people get carried away and move on to other things. Continuous improvement is not sustained, and the previous improvements become the new normal. As a result, employees do not develop a culture of problem-solving and being responsible for their contribution to the flow of value. Unwillingness to embrace new technology and techniquesFrom concerns about migrating data from one platform to another, to employees not being willing to give up their old way of doing things for better ones, changes in techniques and technology can pose a huge problem when implementing operational excellence. Inadequate sponsorship and support from all leadersOperational excellence requires resources and serious commitment. When every leader understands the importance of OpEx and commits to making it work, it’s easier to create and sustain transformative change in any organization. Also, if every leader is onboard, it’ll be easier to allocate the adequate resources (people, time, space, money, tools, etc.) required to implement change. Inability to achieve an enterprise-wide operational excellence strategyMost companies begin their operational excellence journey by creating a small team of people whose main focus is to innovate and find new ways to improve processes. With this approach, changes are easy to implement because there aren’t many people or departments involved. Hence, less time and resources are required. The results of this approach are often short-lived. Because only a few employees are allowed to participate in transformative change, the values and culture of other employees remain the same. A more holistic end-to-end approach is required to ensure that the new culture is spread across different departments. This will require more time and resources to train employees, but the result is a more sustainable and operationally excellent culture. How to Overcome Operational Excellence ChallengesThe following four suggestions for overcoming operational excellence challenges were made by McKinsey & Company after their global survey of organizational transformations. Twenty-six percent of respondents succeeded in implementing company-wide transformations and sustained improvements. After asking the successful companies about the actions that contributed most to their success, McKinsey found that the following four actions correlate much more with success than others. Constantly communicate progressCommunicating progress and success to the different employees and departments while implementing company-wide change was seen to have a direct correlation with success. McKinsey found that respondents who communicated openly with their teams were eight times as likely to report a successful transformation as those who said this communication did not happen. It also helped when senior managers communicated a change story to keep employees aligned around the same goals. McKinsey also found that teams of employees that begin their days discussing the previous day’s results and the current day’s work were twice as likely to succeed. Lead, don’t manageTransformations are 5.3 times more likely to be successful when senior leaders model the changes they’re asking employees to make in their day-to-day activities.  Source Source

When implementing operational excellence, it is beneficial for managers to spend less time planning to implement change and more time with employees. Spend time with them and model the kind of culture, habits, and values you’re trying to help them cultivate. Choose the right people, and empower themKeep people who are resistant to change out of leadership and influencer roles. When undergoing company-wide transformation, senior managers should allocate accountability roles to high performers and active supporters of the changes and innovations being made. McKinsey found that teams are 2.7 times more likely to succeed at implementing change when a high-performing employee or manager is assigned the role of “initiative leader.” They also found that these teams were 3.9 times even more likely to succeed when these initiative leaders were given clearly defined metrics and held accountable for contributions to the transformation. Prepare for continuous improvementTo keep your employees from backsliding into their old ways, ensure that they continue to participate in activities that help them connect strategy to daily work. Keep challenging them to deliver value more efficiently to customers, contribute their best ability, and discover better ways to perform tasks. In McKinsey’s survey, 40% of respondents said they wish they had spent more time thinking about how their organizations would continue to improve. McKinsey reported that organizations that plan for continuous improvement after a transformation were more likely to succeed. Hiring an Operational Excellence Manager

To successfully implement operational excellence in your organization, it helps to have a few team members with significant experience in at least one operational excellence methodology. The goal is to make operational excellence principles a part of the company culture. In most organizations, executives prefer to hire an operational excellence facilitator (also called an operational excellence manager or director) to lead the change. This chapter will discuss the different qualifications, competencies, and responsibilities of an operational excellence manager. (Interested in a general guide to hiring?) Qualifications and Core Competencies of an Operational Excellence ManagerAn operational excellence manager in your organization should have: 5+ years experience working in your industry.Excellent interpersonal and communication skills.Experienced in managing complex and sensitive operational challenges.Adept at identifying issues, identifying their root cause, and finding a solution.Well-developed verbal and written communication skills.Broad knowledge of financial management for budgeting and profit plan obtainment. Health and safety awareness and knowledge (depending on your industry). Responsibilities of an Operational Excellence Manager Leadership. An operational excellence manager will be responsible for leading the organization on a continuous journey of sustained improvement. Develop projects through the best operational excellence methodologies for the organization. Facilitate meetings with management to review and examine project progress.Responsible for the preparation, execution, and sustainability of improvement projects in the organization.Measure the results and progress of operational excellence projects against the operational excellence roadmap.Mobilize commitment for change and enable the continuous sustainment of change initiatives. Recommended Reads and Content for Operational ExcellenceHere is a selection of recommended blogs, books and even a slideshow presentation to complement your research. Recommended operational excellence blogs Institute of Operational ExcellenceInstitute of Operational Excellence is the leading educational center guiding transformations through a range of resources designed to help businesses achieve operational excellence. BTOES InsightsBTOES Insights is the content portal for business transformation and operational excellence opinions, reports, and news. All About LeanAll About Lean shares different aspects of lean manufacturing and lean administration with a strong focus on practicability. Kevin Meyer’s BlogKevin Meyer is co-founder of Gemba Academy, a company that provides over 1,500 online lean and Six Sigma training videos to over 2,000 organizations worldwide. On this blog, Meyer shares his OpEx expert opinions and thought pieces. A Lean Journey: The Quest for True NorthThis blog shares lessons learned by experts along their lean journey in the quest for the true north. Recommended Operational Excellence Books The Discipline of Market Leaders: Choose Your Customers, Narrow Your Focus, Dominate Your Market

This book was written by Michael Treacy and Fred Wiersema in 1995. It discusses the three business strategies companies can use to compete and ultimately position themselves as market leaders. It is based on five years of research by the authors into companies such as Walmart, Dell, Southwest Airlines, Cott, Airborne Express, Atlantic Richfield, Home Depot, Intel, and Sony. Design for Operational Excellence: A Breakthrough Strategy for Business Growth

Kevin J. Duggan wrote this book. It defines why companies embark upon continuous improvement—and the true answer is not to improve efficiency, quality, or eliminate waste! The reason is to achieve operational excellence. Operational Excellence: Journey to Creating Sustainable Value

John S. Mitchel wrote this book. It provides the foundation and tools essential for an enterprise to develop a culture of operational excellence. The Toyota Way to Continuous Improvement: Linking Strategy and Operational Excellence to Achieve Superior Performance

This book was written by Jeffrey K. Liker and James K. Franz. It builds upon the international bestselling Toyota Way series of books by Liker. It looks critically at lean deployments and identifies the root causes of why most of them fail. The Lean CEO: Leading the Way to World-Class Excellence

Jacob Stoller wrote this book. It documents deep insights from interviews with some of the best-known, lean-practicing CEOs. It shows how to implement lean in virtually every type of company and facet of an organization. Recommended Operational Excellence Presentations Ronald Shewchuk: Operational Excellence: Getting Started Frequently Asked Questions About Operational Excellence What is Functional Excellence?

What is Functional Excellence?

Functional excellence and operational excellence do not mean the same thing. While operational excellence is focused on optimizing processes and making employees more responsible for their contribution to the flow of value, functional excellence is about demonstrating a depth of knowledge and skill in a technical or functional area. A functionally excellent employee is always aware of advances and the current thinking in their field. They are happy to accept and integrate new technology to help them perform their tasks more effectively. Some characteristics of functionally excellent employees include: They are recognized as high performers and often asked for advice by peers and leaders. They keep up-to-date with every major professional or technical development in their industry. They demonstrate knowledge of broader themes and trends beyond their area of expertise.For directors and executives: They know what expertise exists in the company, where to find it, and how to leverage it.They anticipate the risk of losing critical talents and develop effective succession plans. What is the Shingo Prize?The Shingo Prize is an award given to organizations worldwide by the Shingo Institute, a program of the Jon M. Huntsman School of Business at Utah State University in Logan, Utah. The Shingo Prize is based on a complete assessment of an organization’s culture and how well it drives world-class results. To be selected as a recipient of this award, organizations must “challenge” or apply for it by submitting an achievement report that provides data about recent business improvements and accomplishments. Shingo Institute examiners will then visit the organization for an onsite assessment. The following three qualities determine whether or not an organization will qualify for a Shingo Prize: The degree to which the Guiding Principles in the Shingo Model are evident in the behavior of every employee. The examiners observe the behavior and determine the frequency, duration, intensity, and scope of the desired principle-based behavior. The degree to which leaders focus on principles and culture. How committed managers are to aligning systems that drive ideal behaviors at all levels. What is the Okapi Method in Operational Excellence?Okapi is one of the methods for achieving operational excellence. It was developed by Iris Tsidon and Maya Gal of Okapi, a platform for improving organizational management. The Okapi method helps organizations lower costs while boosting production using SMART key performance indicators. S – Specific: to create a clear focus for employees, operational excellence KPIs must be as precise and specific as possible. This way, employees are clear on what success is for them and can strive toward it. M – Measurable: having measurable actions as KPIs helps employees know where to increase or relax their effort. A – Achievable: KPIs should be challenging but attainable.R – Relevant: always have the objective you’re trying to achieve in mind when selecting KPIs. The more relevant your KPIs are to your end goal, the easier it is for your team to help you get there.T – Timely: employees should always have a deadline for completing tasks and achieving goals and objectives. What is Flawless Execution (FLEX) Methodology?Flawless execution methodology (FLEX), also popularly known as the PBED methodology (PBED meaning plan, brief, execute, and debrief), was adopted by businesses in 1998. Fighter pilots initially developed it to achieve operational excellence in combat. The FLEX methodology involves creating an execution plan for achieving operational excellence and constantly adapting the details of this plan to fit changing influences in the real world. It starts with creating a plan (P), briefing your team about this plan (B), executing this plan to the best of your ability (E), and debriefing your team based on the measured results from your execution strategy while making relevant suggestions to improve this strategy (D). What is Value-Added Work?Value-added work refers to the steps in a process that add value and are essential in the eyes of the customer. Example: A student hires a painter to paint his room. One hour after the painter arrives, he realizes that he doesn’t have all the tools required to finish this job. He spends two hours commuting from his customer’s room to his workshop to get his tools. The painter returns and finishes his job in an hour. In this example, the time spent by the painter getting his tools does not count as valuable to the customer. The only work that the customer considers valuable is the time spent painting the room. The concept of value-added work can be applied to various service-oriented businesses. To apply it to yours, simply follow these steps: Step 1: List out all the steps involved in performing a service. Step 2: Determine the steps that add value to the customer and those that don’t. Step 3: Try to take out as many of the steps that don’t add value to the customer where possible. Step 4: Calculate your value-added ratio and try to get it to at least 20–40%. Value-added ratio = Value added time/total time In typical processes, the value-added ratio is only about 5–20%, which means 80–95% of the process doesn’t add value to the customer. You may never be able to get rid of all the non-value-added time but try as much as you can to move yours to about 20–40%. Ready to Reap the Benefits of Operational Excellence?Suppose you’re ready to create more operationally excellent processes, develop a culture of teamwork and continuous improvement, and position your organization for future success. In that case, we’d like to help you get started. We have created an operational excellence implementation plan to help jumpstart your OpEx journey. You can also claim a free 14-day trial for SweetProcess. This tool helps you attain operational excellence by allowing you to document processes, procedures, and tasks in one place so you can stay focused on growing your business. With SweetProcess, you can: Document procedures and repetitive tasks. Create, share, and ensure correct adoption of your business’s policies.Craft, collaborate and refine processes so that your organization can continue to grow and improve. Manage tasks, track all the latest activity, or look back at any task or procedure history.Turn your existing procedures and policies into a knowledge base for your employees or clients. Related Posts:

Related Posts: Why Your Mindset Is the Key to Achieve Operational Excellence Why Your Mindset Is the Key to Achieve Operational Excellence Building an Efficient Project Management Team for Operational Excellence Building an Efficient Project Management Team for Operational Excellence Creating a Standard Framework for Remote Team Success Creating a Standard Framework for Remote Team Success How MonteVista Homes Helps Homebuyers Achieve the American Dream with Streamlined Business Processes How MonteVista Homes Helps Homebuyers Achieve the American Dream with Streamlined Business Processes Cultivating a Collaborative Culture to Achieve Common Goals Cultivating a Collaborative Culture to Achieve Common Goals 11 Internal Communication Tools For Your Remote Company

Get Your Free Systemization Checklist 11 Internal Communication Tools For Your Remote Company

Get Your Free Systemization Checklist

5 Essential Steps To Getting a Task Out of Your Head and Into a System So

You Can Scale and Grow Your Business!

5 Essential Steps To Getting a Task Out of Your Head and Into a System So

You Can Scale and Grow Your Business!

May 2nd, 2021

Business

by Laura Varon

Leave a Reply Cancel reply

May 2nd, 2021

Business

by Laura Varon

Leave a Reply Cancel reply

|

【本文地址】